Product Types

Motor Development Capability

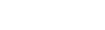

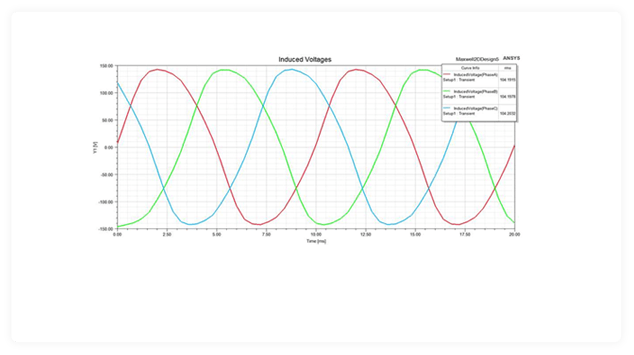

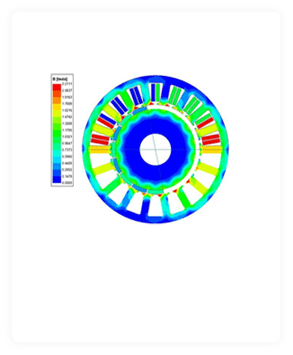

1.1)Electromagnetic Simulation Analysis

Back EMF Distribution

Magnetic Density Distribution

Magnetic Line of Force Distribution

1.2) Mechanical & Thermodynamic Simulation Analysis

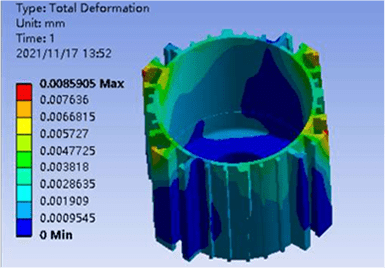

Stress Analysis of Frame

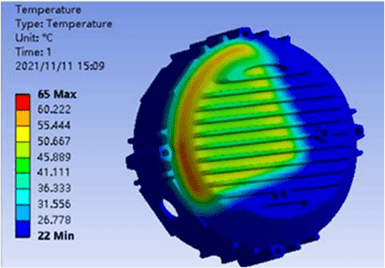

Thermodynamic Analysis of Control Cover

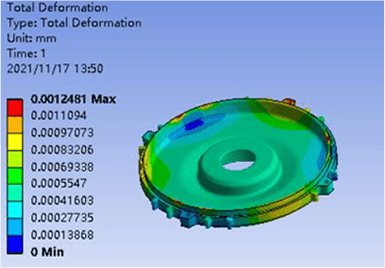

Stress Analysis of Rear Cover

Optimized product design to improve material utilization to enhance the competitiveness of product cost. (Green Design)

Reduced schedule of development to deliver products to customer on time. (Time To Market)

Guaranteed quality cost minimization. (Design For Six Sigma)

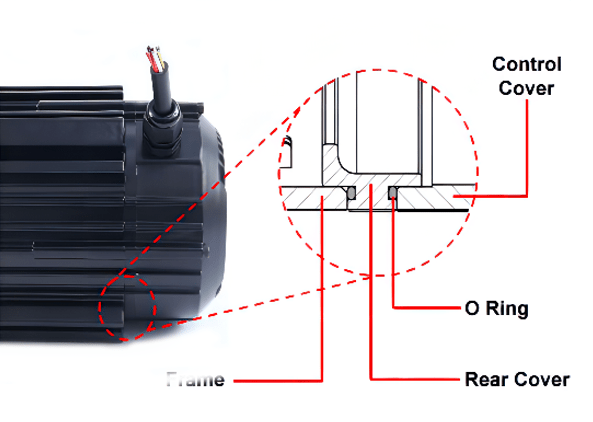

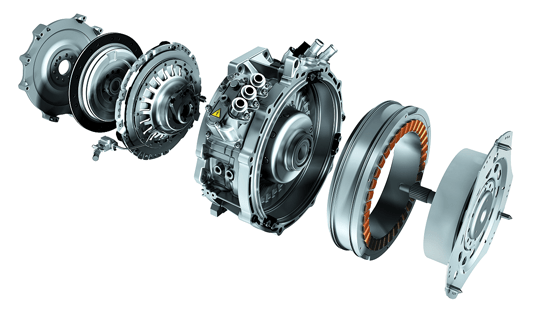

1.3) Innovative structural design

Front Cover Merged with Frame

Reduces motor assembly process

Improves tolerance stack-up

Eliminates risk of waterproof failure resulting from mechanical connection

“Sandwich” Structure Design of Rear Cover

Eliminates redundant connecting of parts

Simplifies assembly process

Reduces total length of motor

Potting Process for Motor Control

Improves motor control heating dissipation

Improves waterproof capacity of control

Eliminates risk of loose electrical components

Changzhou Rasta Electromotor Co., Ltd. was founded in Jan. of 2021. Seamlessly combining research, manufacturing and sales, Rasta specializes in producing ECM (Electronically commutated motors), which are made with a permanent magnet motor, integrated with an electronic control module, commonly used in commercial and industrial areas such as high negative pressure axial ventilators and pumping.

Rasta has excellent R&D capabilities and has become the "Engineering Technology Center for High Energy and Low Consumption Permanent Magnet Motors" and has been granted several patents in China.

Our Product Strengths

As a company, we are committed to helping our clients achieve success.

High Efficiency

Save more than 25% energy than lnduction Motor at same working condition

Small Size

Compact structure design, with around 20% smaller size than competitor's

Competitive Cost

Utilize simulation analysis to optimize product design to maximize the contribution of raw material

Strong Overload Capacity

Provide stable running speed under high negative pressure condition of Ventilation system

lntelligent Control

With multiple electronic protection functions, provides foundation for the system of intelligent centralized control

Light Weight

More than 30% lighter than Induction Motor

Why Choose Us

We have more than 10 years of service experience worldwide. We have successfully completed cooperations in tool production in more than 20 cities around the world.

Professional motor design, professional manufacturing and quality management team

Rasta’s professional motor design team guarantees the high quality of each motor., and the team's outstanding R&D abilities have been awarded several patents.

High quality raw materials and parts

Rasta strictly controls the high quality of raw materials, and we have maintained multiple partnerships with parts manufacturers for more than a decade.

Well-known domestic high precision molds and equipment for key processes

Rasta pays attention to each process of motor production. We invest more in equipment and molds every year, and through our own continuous innovation, we are able to improve our basic production capacity and respond to the needs of the motor market.

Total quality management to control the production process

Rasta has a quality control team of 15 people. Our motors are tested three times before the customer receives the product to ensure a 100% product qualification rate.

FAQs

Where are your products made?

Our products are manufactured in Changzhou, China. Rasta has excellent R&D capabilities and has become the "Engineering Technology Center of High Energy and Low Consumption Permanent Magnet Motors”. Rasta has obtained several patents in China. Since its establishment, the company has been serving customers with the philosophy of "Every delivery to the market is a promise”.

Rasta EC80 series motors are Class F. Max allowable motor winding temperature: 155°C. Max measured temperature of the 2.2kW motor is 98°C.

The motor protection level is IP55.

The surface of the motor casing and end cover is made of an imported PPG powder coating, and it is rated up to 700 hours.

2 years warranty.

Front bearing – 6305-2RS; Rear bearing – 6205-2RS.

0.375~1.1kW motors use C&U domestic famous brand bearings; 1.5~2.2kW motors use NSK Japanese imported bearings.

- The motor casing and the front cover adopt a one-piece structure, directly eliminating the connection between the front cover and the casing.

- There is an O-ring seal between the casing and the end cover, using the end face seal structure design.

- The contact surfaces of the housing and the end cover are machined to ensure flatness of the end surfaces.

- The motor is assembled with additional sealant between the casing and the end cover to provide a double-sealing effect.

- The motor uses a domestic well-known shaft seal.

- The front bearing is sealed with a rubber cover.

- 0~10V voltage commissioning

- 485 communication

- Over-current

- Over-temperature

- Overload

- Under-voltage

- Along with blocking, phase loss and protection functions.

For HVAC applications.

0.375~2.2kW motors, weight 7.6~13kg respectively

0.375~2.2kW motors, weight 7.6~13kg respectively

What Our Customers Have to Say

Different reviews from different customers

Ramdn Z.

The system is very good

"I’ve used Rasta motors for some time now and noticed that Rasta motors energy consumption is 10% less than other companies. They are quieter, stronger and operate smoothly with no problems. I always have a very good shopping experience with Rasta”.

Ramdn Z.

The system is very good

“I've never used such an awesome motor. It came very well-packaged when I received shipment, so obviously the merchant protected my product very well. The motor has full horsepower, low losses, a low price and is very easy to use; a true value for the money”.